Craven Equipment - Luggage for Classic and Modern Motorcycles - Made in Britain

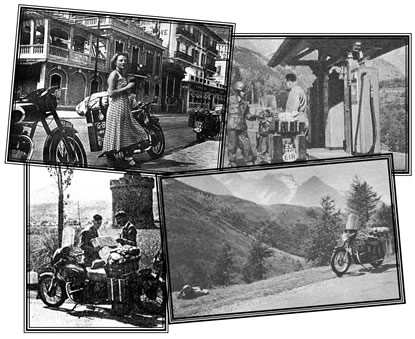

Inspired by Adventure -

Craven Equipment is an iconic brand, combining classic looks with modern methods. Using original moulds and designs we have retained the distinctive Craven look while incorporating modern fixtures to ensure each piece stands the test of time. Owners of original luggage can also repair and restore their luggage using our accessories, or uprate them with improved fittings.

Built for Everyday -

Where possible we only use non-ferrous fittings to ensure each piece of luggage looks as good as the day it was made. Our shells are coloured using gel all the way through the fibreglass, not just a top coat. This means any scratches will only reveal the same colour as your luggage, making them less visible and your luggage looking better for longer.

Security & Service -

While the design of Craven boxes is the same as it has always been, the locks and fastenings have been uprated. Drill-proof locks, Torx security screws and stainless nyloc nuts all ensure the security of your luggage. Sets of luggage bought at the same time will all use the same key. To care for your luggage simply wash with soapy water and a soft, clean cloth. Using Autoglym Resin Polish (or similar) will give a high shine and a liquid sealant or hard wax suitable for resin will further protect the surface. Standard touch-up pens will help cover scratches.

Made In Britain -

All our racks, panniers and topboxes are made in house from start to finish. The bespoke components for our fitting kits are also designed and cut in our workshop. Sundry items that we buy in are sourced from the UK where possible. Our stickers are made less than 30 miles from our shop! We employ talented local people who have a passion for their craft and an eye for detail.

Our History

Ken Craven was initially a reporter, taking his motorcycle abroad to write articles, and it seemed that every story contained some kind of peril or adventure. For example, while reporting on the Civil War in Spain in 1937, he and his 1931 Dunelt were shot at. Apparently the insurgent pilot had spotted him after seeing the nickel plate on the side valve's petrol tank!

After marrying Mollie, and ‘converting’ her to the joys of motorcycling - "I have had many, many long walks alongside that machine" - Ken and Mollie Craven were now both inveterate motorcycle tourers, taking Hetty, their Matchless, across Europe. They would think nothing of doing 1300 up to 4000 mile trips. Later on, possibly as a result of their adventurous reports in the motorcycle press, they began to take like-minded souls on "Parti-tours" to Spain and other European destinations. At that time there was little, if any, luggage equipment available for motorcycles other than ex-WD panniers. Ken, an engineer, realised that there was a demand and came up with luggage equipment to do the job.

In 1946 Ken created his first set of panniers “built and designed to simplify, even to avoid all baggage problems”. The first panniers were made from a compressed fibre board and had square corners with metal strapping or banding around them, a feature that remains to this day. The early efforts of other companies tended to disappear, as the volumes they sold did not tend to be great and, as the product improves with time, early versions are disposed of to be replaced with 'new and improved' ones. So it is a testament to the quality of the original Craven design and manufacture that there are many of our really early panniers still around.

It wasn’t until 1952 however, that a manufacturing company called Craven Equipment was formed, based in Eden Grove, London and was to dominate the motorcycle luggage market for nigh on 30 years.

Ken later retired from the business and sold it to Stadium Ltd, known for their helmets and other motorcycle accessories. Ernest ‘Jim’ Lockwood had worked for Ken since the late 60s, and had been a consultant during the Stadium ownership. He subsequently bought Craven from Stadium in the early eighties and he and his son continued production from their location in the Forest of Dean in Gloucestershire. This company, Gepek, was in the business of fabrications and making various things from glass fibre, including police dog cages, and was a family affair. Not long before this company ceased trading, due to the passing of both father Jim, in '82 or '83, and son Graham in the mid-nineties, the Craven part of the business was sold to Phil Primmer's company, West Country Sidecars, but after a few years he himself was to retire, hopefully to ride his Vincent to the furthest reaches of Europe and beyond.

In 2007 Draganfly Motorcycles bought Craven Equipment from Phil and began to run it as a sister company. After three years of slow progress, they refurbished the machine tools, jigs and moulds in order to start production in 2011. A lot of the equipment was in poor condition, although most of the moulds were pretty good. There was virtually no stock but there were a lot of drawings, however the part numbers on them did not match the samples that Draganfly acquired and further still, did not match the numbers on the instruction sheets! As the Craven system is made up of five standard racks and about 20 styles of panniers all held together by a unique set of brackets for each motorcycle, without a list of which bit was for which bike made providing fitting kits difficult!

In 2016 after several unproductive years working with outside companies to manufacture Craven’s fibreglass luggage, we made the big decision to take control of the entire process ourselves. We brought everything in-house, from manufacture to assembly, quality control to dispatch. A large area was cleared in our workshop, with several bikes being moved for the first time in nearly 20 years, and production started. Our lad Harry was the first person to manufacture for us with Graham following shortly after. Not only did this enable us to control the entire process but also allowed us to develop new pieces, which proved to be an exciting time after spending too long in the slow lane.

With production of the Snowdon, Concorde and Comet models taking priority initially, we also began production of the rest of the range. Unsurprisingly some pieces were much harder to produce than others. For example, the Rodark pannier was originally made in metal from Triumph mudguards and the Silver Arrow panniers were made from what only could be described has hardboard and pieces of wooden battening. Our team not only looked into the best methods to remanufacture these but also the best finish that could be achieved.

In 2017 we launched a new website to reflect our new production schedule and quality of our pieces and we were finally ready to shout about Craven Equipment!

Our Process

Our panniers, top boxes, racks and fitting kits are made in-house, hand-finished to an exceptional standard and closely quality controlled.

We use original moulds so designs are the same as they have always been. Our glass fibre shells are coloured using gel, giving a truer, deeper colour. This also means we can polish them to high shine without wearing away the colour and should a piece be scratched during use, the colour exposed will be the same as the surface so your luggage will look better for longer.

A coating is applied to the inside of each shell to prevent damage to any contents, then fastenings and strapping are hand riveted on with precision. The finishing touch is a hand-applied glossy Craven badge.

We are proud of each piece of luggage that leaves our workshop and we hope that you will be as proud to take them with you on your travels.

Craven Equipment is owned by Draganfly Motorcycles Company No. 08451344 VAT GB160988281